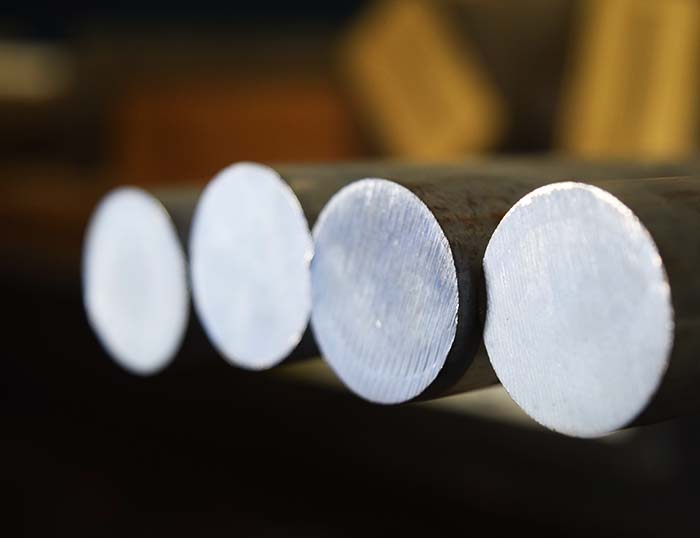

AZ31B Magnesium

Rapid Machining

A wrought magnesium alloy offering good room temperature strength.

AZ31B magnesium alloy benefits from increased strength and density due to strain hardening with partial anneal (H24 and H26 tempers).

Overview:

Magnesium is considered a highly viable alternative to aluminium and titanium, as it benefits from very low density while still offering strength. AZ31B falls into this category and is one of the most readily available magnesium alloys. Our product offers excellent weldability and can be machined faster than any other metal. The material is non-magnetic with high electrical and thermal conductivity.

Machining & Welding:

Machining provides good machinability, although precautions are required due to the alloy's flammability. A suitable lubricant is required during the machining process, which should always be closely monitored. The alloy is weldable using gas tungsten arc welding and metal arc welding methods. Pre-heating is required before forming.

Uses in motorsport:

AZ31B magnesium alloy is highly suitable for producing intricate motorsport parts. Race chassis, monocoque construction, hydraulics and structural engine parts may all benefit from using AZ31B. Magnesium is lighter than both aluminium and titanium, so is highly beneficial in maintaining a good strength-to-weight ratio.

Talk to the Experts:

We gain a clear understanding of our customers' design drivers. By pushing the boundaries of both chemical and mechanical properties, we supply materials that deliver enhanced overall performance. Give us a call on +44 (0)1767 604708 or alternatively, click here to contact us.

- Good ductility

- Good corrosion resistance

- High electrical and thermal conductivity

- Good strength at room temperature

- Production of intricate motorsport parts

- Monocoque construction

- Racing chassis

- Structural engine parts & hydraulics