Nimonic® 90

(UNS N07090)

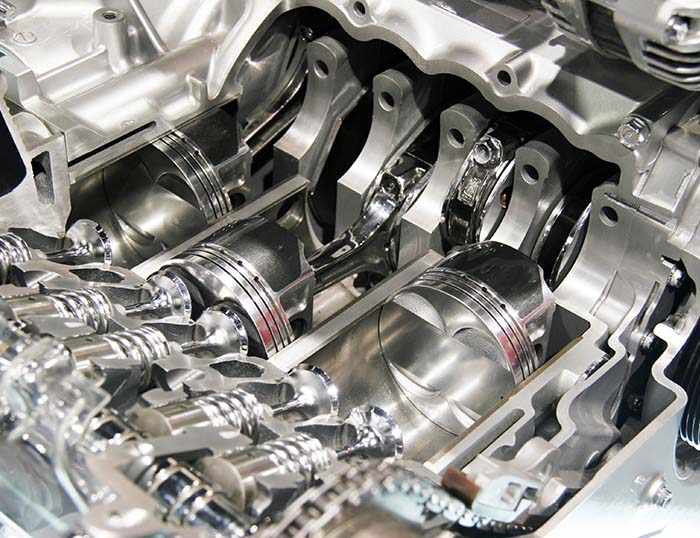

High-Stress Performance

Nimonic® 90 is a nickel-chromium-cobalt alloy which is precipitation hardenable.

Offering high stress-rupture strength and creep resistance at elevated temperatures up to 950° C (1740° F), this wrought alloy is highly suitable for high temperature and high mechanical stress applications.

Strength:

Its derived strength is due to the addition of aluminium and titanium in the alloying process. The material offers good resistance to high-temperature corrosion and oxidation.

Machinability & Formability:

Nitronic® 90 is machinable after heat treatment using conventional machining methods with commercial coolants. Higher-speed machining operations (turning, milling, grinding) should be performed using water-based coolants. When boring, drilling or tapping, a heavy lubricant is required. The alloy can be formed using basic conventional techniques.

Applications:

Traditionally used to produce gas turbine blades and hot working tools, Nimonic® 90 is also popular in the motorsport and automotive sector. The alloy finds use in high mechanical stress and high-temperature applications, including specific engine applications, high-temperature springs and high-performance engine valves. The product is ideal for high-boost pressure turbocharged applications.

Weldability:

Welding on solution-treated material is required, and a post-weld heat treatment is necessary to achieve optimum results. The alloy can be welded using conventional welding techniques.

- High stress-rupture strength

- Good high temperature corrosion resistance

- Suitable for high stress applications

- Weldable by conventional methods

- Engine components

- High temperature springs

- High performance engine valves

- Turbocharger applications