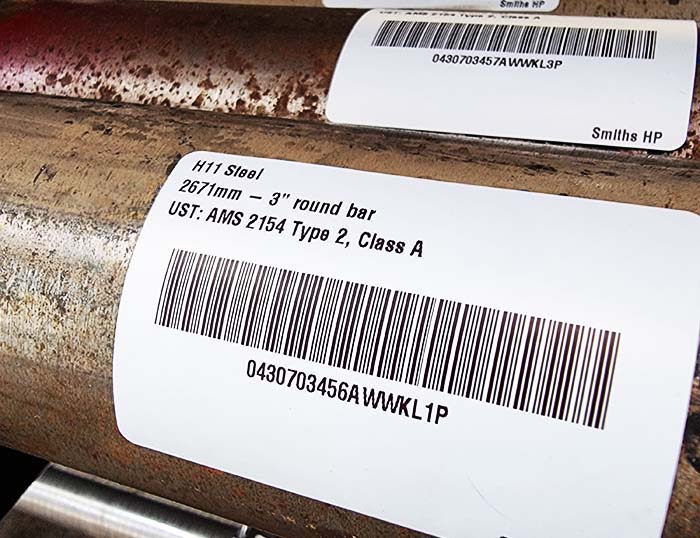

H11 Tool Steel

(1.2343)

Outstanding Impact Toughness

H11 Tool Steel is one of the most commonly used hot-worked steels on the market.

The alloy's main characteristic is outstanding impact resistance.

Impact Resistance:

H11 contains less vanadium when compared to other 'H' series tool steels, which improves impact resistance but reduces wear and temper resistance. The alloy also offers superior resistance to thermal fatigue cracking and thermal shock. H11 is highly suitable for applications requiring the highest cracking resistance.

Production:

H11 is often referred to as H11 ESR because alloy production is via the electro-slag refining process. Although increased vanadium reduces temper and wear resistance, the alloy promotes excellent temper resistance and toughness. Minimal distortion is also observed during deep hardening and air hardening resulting from well-balanced chemistry.

Use in Motorsport:

Tool steel finds considerable use in race engine production, and H11 is no exception since tool steels offer improved performance compared to general engineering steels. Effective cracking resistance and minimal distortion are positive attributes which make H11 tool steel highly effective in producing race engine components. Double or triple tempering may be required to unlock the enhanced performance characteristics of the alloy.

Talk to the Experts:

We gain a clear understanding of our customers' design drivers. By pushing the boundaries of both chemical and mechanical properties, we supply materials that deliver enhanced overall performance. Give us a call on +44 (0)1767 604708 or alternatively, click here to contact us.

- Outstanding impact resistance

- Resistance to thermal fatigue cracking

- Excellent toughness

- Well-balanced chemistry

- Drivetrain components

- Cranktrain components

- Camshafts

- Gears