7075 Aluminium

For critical strength applications

7075 finds use in engineering applications demanding high material strength without requiring corrosion resistance.

7075 aluminium alloy benefits from high tensile and yield strength, which is temper specific, and the alloy also offers improved stress corrosion resistance (SSC).

Suitability:

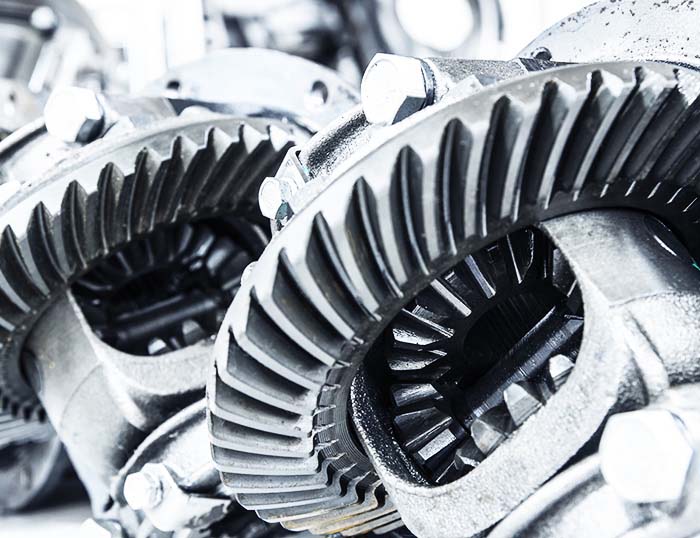

The product includes zinc in the alloying mix, which increases strength but at the expense of corrosion resistance. The alloy is suitable for applications which are susceptible to high stresses, such as differential gears and driveshafts. Our product is also an ideal solution for applications where weight reduction is critical.

Other Characteristics:

7075 aluminium alloy offers an impressive strength-to-weight ratio, with comparable strength to steel and titanium but with less weight. The alloy is also non-magnetic and non-sparking and can be highly polished, leaving an aesthetically pleasing finish.

Welding & Machining:

The material does not provide the same levels of weldability and machinability capabilities compared to other commercial aluminium alloys. It only offers fair machinability, while weldability is susceptible to stress corrosion cracking.

Where performance matters:

When you purchase high-performance materials from Smiths High Performance, you will join some of the biggest and best global engineering companies. We are a Tier 1 supply chain partner to the world's leading motorsport companies. Our unique business structure and ethos allow us to offer services otherwise unavailable in this market sector.

- Very high strength

- Excellent strength-to-weight ratio

- Non-magnetic and non-sparking

- Easily polished

- Driveshafts

- Sprockets

- Differential gears

- Bulkheads