BS S106 Steel

Chrome-Moly Nitriding Steel

BS S106 benefits from a hard outer casing once heat treated.

The alloy is produced by vacuum arc remelting (VAR) or air melting, resulting in a material with excellent transverse properties.

Overview:

BS S106 offers excellent wear and abrasion resistance characteristics and performs well in high-temperature applications. Additional performance benefits include medium tensile strength and high fatigue strength.

Stock Info:

We stock BS S106 chromium molybdenum bright steel bars, which we supply in the hardened, tempered and stress-relieved delivery condition. EN40B (744M24) engineering steel is an equivalent material grade. We also provide in-house billeting services to cut your bars to specific lengths.

Applications:

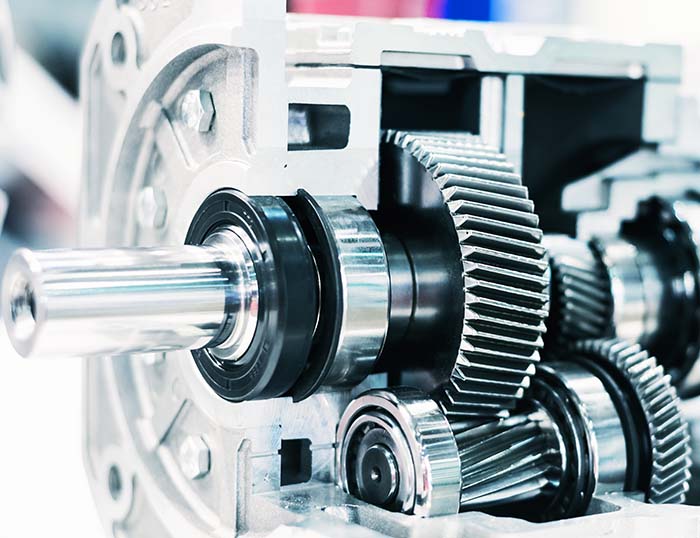

Motorsport applications include gearbox shafts and crankshafts. BS S106 is ideal for applications requiring fatigue, wear and abrasion resistance with moderate strength. Steel alloys are utilised in motorsport application areas where weight-reduction is not a factor.

About SHP:

Smiths High Performance is a leading stockholder and supplier of high-performance engineering materials. We are material supply chain partners supporting high-technology motorsport market sectors, including Formula 1 and MotoGP.

- Case hardened

- High fatigue strength

- Excellent wear & abrasion resistance

- Medium tensile strength

- Crankshafts

- Gearbox shafts

- Spindles

- Gears