2055-T84 Aluminium Lithium

High Strength, Fatigue Resistant, Low-Density Extrusions

For motorsport & aerospace applications.

We have developed Al-Li alloy 2055 extrusions for use in motorsport, aerospace and other applications requiring high tensile or compressive strength, high modulus, high fatigue resistance and low density with good fracture toughness and corrosion resistance.

Low Density:

Lithium additions increase the strength and modulus of aluminium lithium alloys while lowering their density. The density of 2055 is 4 to 5% less than high-strength 7xxx. 2055-T84 extrusions exhibit superior machining, finishing and forming characteristics.

Applications:

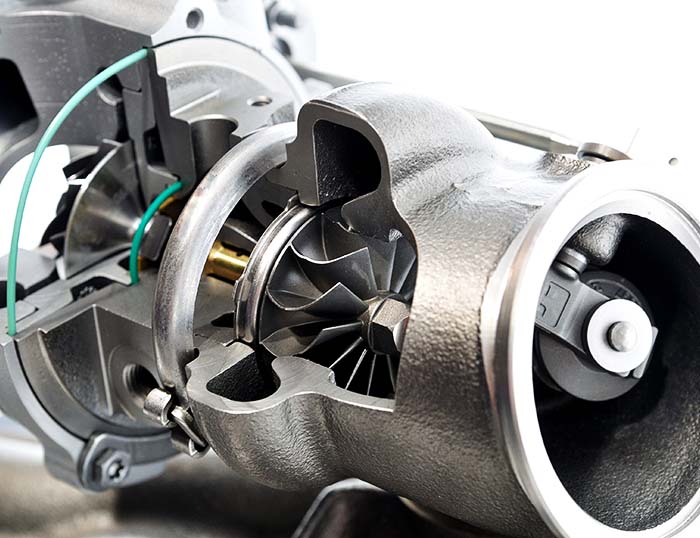

The combination of high strength, stiffness, damage tolerance and durability makes 2055 suitable as a replacement for high-strength 7xxx and 2xxx alloys in applications such as fuselage stringers, floor beams, compressor wheels, turbo impellers and other statically and dynamically loaded applications requiring high strength and stiffness.

Toughness & Fatigue:

The damage tolerance and durability properties of 2055-T84 extrusions are superior to high-strength 7xxx extrusions providing an improved combination of strength and toughness, improved fatigue crack growth resistance, and S-N fatigue resistance.

Commercial Status:

Alloy 2055-T84 extrusions are covered by AMS 4257. Material design allowables, including static properties, physical properties, fracture toughness, corrosion resistance and S-N fatigue, are available in MMPDS.

- Superior damage tolerance and durability

- High strength

- High stiffness

- Low density

- Statically and dynamically loaded applications

- Turbochargers

- Floor beams

- Compressor wheels