Ti 6246 Titanium

Alpha-Beta Titanium Alloy

Our product is ideal for high-technology components such as racing engines & drivetrains.

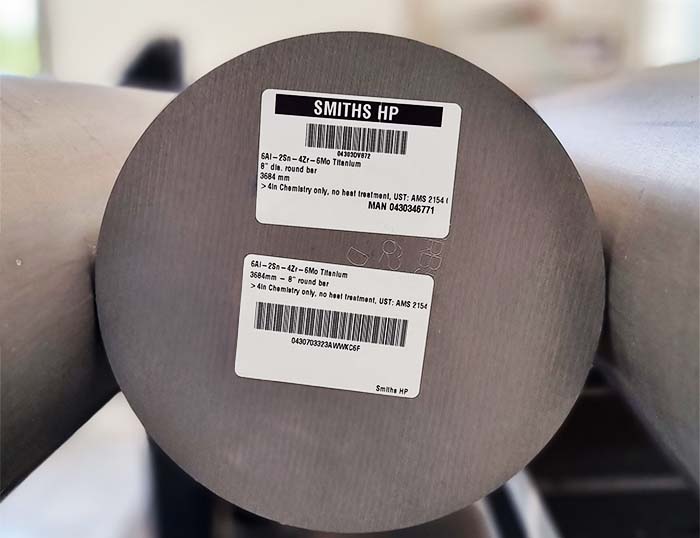

6246 Titanium Alloy (a stronger derivative of 6-2-4-2) is an alpha-beta titanium alloy offering superior high mechanical strength and toughness with good retention up to 460°C.

Introduction:

The alloy is heat treatable, which can achieve even high tensile strength. Corrosion resistance is excellent, including reducing environments and saltwater, and the material includes sour service approval to NACE MR-01-75 standard.

Suitability:

6246 titanium is an ideal engineering product for high-strength applications which require excellent corrosion resistance and low density. The alloy has a very high strength-to-weight ratio with good fatigue resistance. Material applications include production equipment in the oil and gas sector, gas turbine engine components in the aerospace sector and the manufacture of precision components for motorsport.

Greater Fatigue Resistance:

6246 titanium contains a more complex microstructure due to thermomechanical processing, which increases strength and fatigue resistance. The resulting alloy is highly suitable for critical aerospace and motorsport components such as engine parts and compressor wheels.

Corrosion Resistance:

The alloy's excellent corrosion resistance also results in a highly effective engineering product for sub-sea and above-sea applications. The alloy is also a highly effective light-weighting material, essential in aircraft and race car manufacture.

- Excellent corrosion resistance

- Even greater mechanical strength and toughness

- Low density

- Good fatigue resistance

- Racing engine parts

- Drivetrains

- Compressor discs

- Fan blades