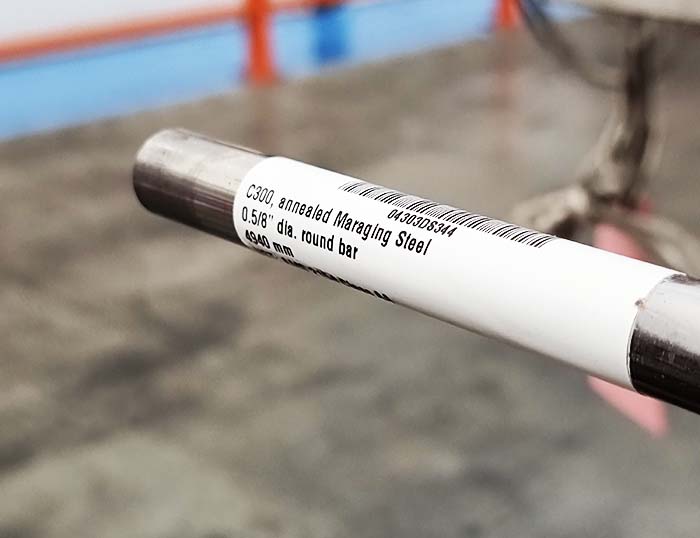

Maraging Steel C300

For strength & malleability

C300 Maraging Steel offers stable properties and weight reduction possibilities while maintaining strength.

C300 maraging steel is age hardenable steel produced to create exceptional toughness and strength. With a nominal tensile strength of 300 ksi, the material can retain its tensile strength up to 450°C. The core alloying elements are iron, cobalt, nickel and molybdenum, and the product offers excellent toughness and resistance to crack propagation. The material may also be nitrided. C300 can be machined close to finished dimensions as the low-temperature maraging treatment results in minimal distortion.

Applications:

In motorsport, Maraging 300 finds use in torsion bars, crankshafts, chassis components and gears. The alloy should be considered for components where strength and toughness are critical, as long as these components to do not add significant weight.

Processing Options:

Maraging steel bars are processed by SHP in-house, utilising dedicated billeting services at our Head Office in Biggleswade. We process bars to close tolerances making us a single supply source for all your engineering raw material needs.

Laboratory Support:

To add further value, our UKAS Accredited Materials Testing Laboratory provides comprehensive metallurgical support, including various testing methods. Our laboratory services are unique to the UK stockholding sector.

About SHP:

Smiths High Performance is a leading stockholder and supplier of high-performance engineering materials. We are material supply chain partners supporting high-technology motorsport market sectors, including Formula 1 and MotoGP.

- Excellent strength and toughness

- Excellent crack propagation resistance

- Readily weldable

- No loss in malleability

- Torsion bars

- Chassis components

- Crankshafts

- Gears