Maraging Steel Alloys

Ultra-high strength steel

Maraging steels are low carbon alloys (no greater than 0.03%)

Our stock range, includes three individual material grades which all benefit from ultra-high-strength and toughness without any loss of ductility. Once heat treated, the alloy has good hardenability and is dimensionally stable. Maraging steels are iron-based with inclusions of nickel, cobalt, molybdenum and titanium.

Case hardness may be improved even further by nitriding. Maraging steel offers good weldability, although the alloy must be subsequently aged to restore the properties within the heat affected zone (HAZ) i.e. the unmelted area being subjected to high temperatures during the welding process. Our products benefit from good machinability once annealed.

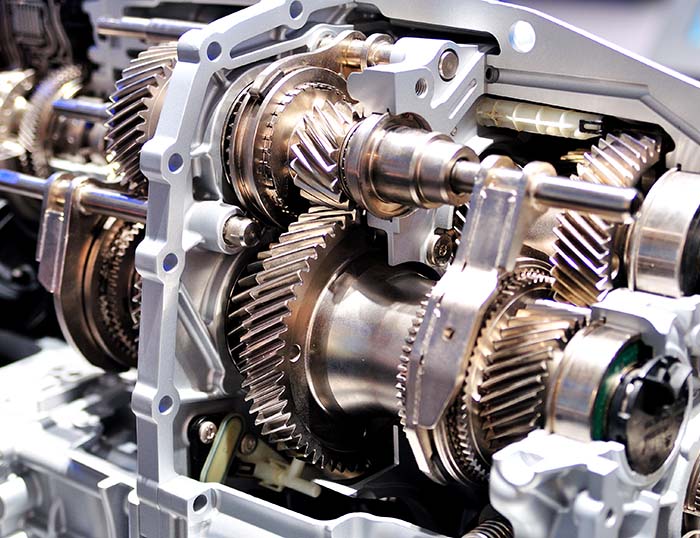

Motorsport Applications

Maraging steels are supplied in solid round bars and therefore ideal for applications involving torsional stresses or twisting.

Driveshafts, torsion bars and crankshafts are obvious examples, taking advantage of the alloys ultra-strength, hardenability and toughness. Gears and chassis components may also utilise maraging steel as an engineering material.

Maraging Steel Range:

Supply Partners

We provide comprehensive engineering raw material support for global motorsport, including Formula 1 teams and their sub-contractors.

DISCOVER