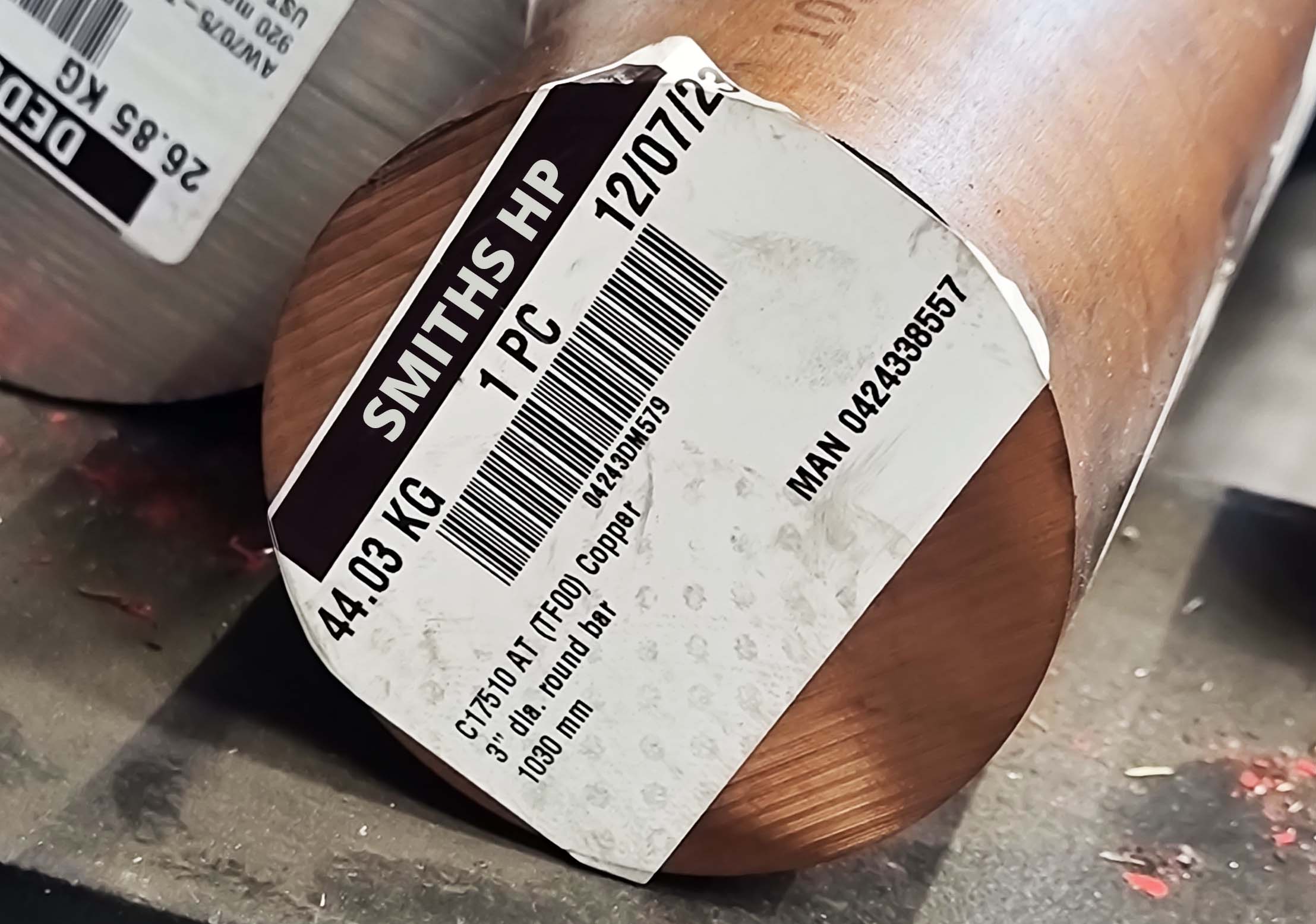

C17510 (Alloy 3)

High conductivity & strength

C17510 (also known as Alloy 3) is a high-conductivity beryllium copper alloy ideal for applications requiring a combination of strength and high thermal conductivity.

Offering corrosion-resistant characteristics similar to pure copper, C17510 is fully heat-treated, and therefore, no further treatments are required. The resulting material is non-magnetic and thermal fatigue is excellent. The general machinability and brazing characteristics of the alloy are also good. The weldability of the alloy is only fair though C17510 is highly weldable to copper. The material is stronger when compared to other copper alloys with superior structural strength.

Applications:

Traditional applications for Alloy 3 include oil and gas applications, particularly in long-reach power and signal solutions. Due to the material's high conductivity and strength, C17510 also offers a variety of motorsport and automotive applications, which include engine compartment connectors, switches and sensor terminals.

Weldability:

C17510 resists stress corrosion cracking in both sulphide and chloride solutions. It is corrosion-resistant to most organic solutions, saltwater atmosphere, non-oxidising acids and diluted alkalis and is not susceptible to hydrogen embrittlement. Use with strong, oxidising acids or ammonium hydroxide is not recommended.

Suitability:

C17510 should be considered for applications requiring high electrical conductivity combined with high strength, especially if the material needs to be machined easily.

About SHP:

Smiths High Performance is a leading stockholder and supplier of high-performance engineering materials. We are material supply chain partners supporting high-technology motorsport market sectors, including Formula 1 and MotoGP.

- High electrical conductivity

- Superior strength compared to other copper alloys

- Non-magnetic

- Very good machinability

- Engine compartment connectors

- Switches

- Sensor terminals

- Coaxial connectors